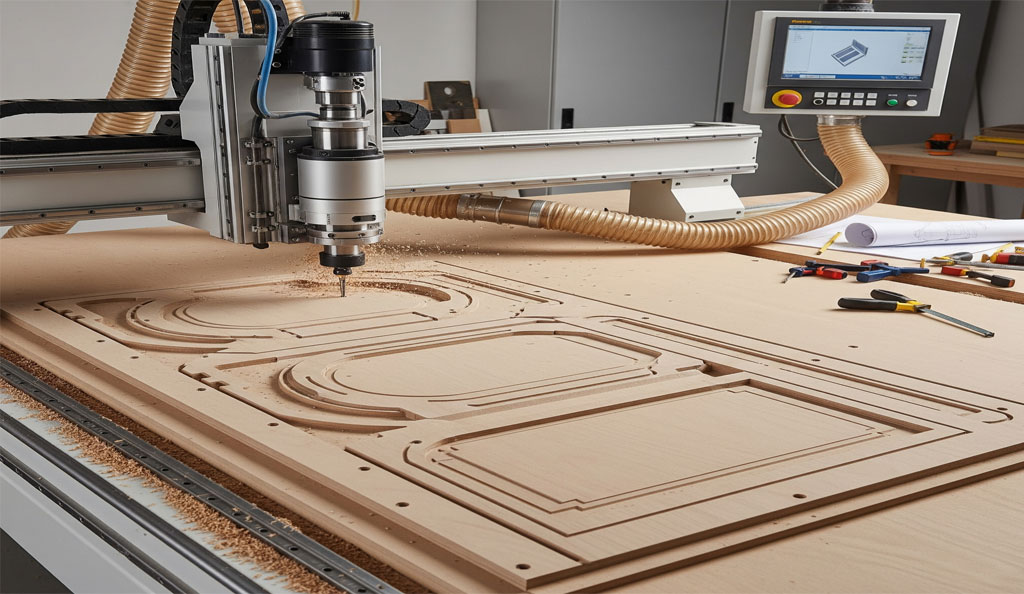

CNC wood routers are popular in furniture and cabinetry making for several key reasons:

- High Precision and Consistency: CNC routers produce highly accurate cuts and carvings with tight tolerances, ensuring that every piece fits perfectly. This consistency is critical in furniture and cabinetry where components must join precisely.

- Increased Efficiency and Productivity: They drastically reduce manual labor and time by automating cutting, shaping, drilling, and carving operations. This allows manufacturers to complete more projects faster, increasing output without sacrificing quality.

- Material Optimization: Advanced CNC software can nest parts to maximize material usage, reducing waste and lowering costs. Efficient material management translates directly to higher profit margins.

- Complex and Custom Designs: CNC routers handle intricate shapes, decorative carvings, joinery, and patterns that would be difficult or impossible to achieve by hand. This expands creative possibilities for custom furniture and high-end cabinetry.

- Versatility: These machines work with a variety of materials—wood, laminates, MDF, plywood—and support multiple operations such as cutting, drilling, engraving, and edge finishing, making them essential in diverse woodworking projects.

- Repeatability: Once programmed, CNC routers can replicate designs endlessly with the exact same dimensions and detail, ideal for mass production or running custom orders consistently.

- Lower Skill Barrier: CNC routers simplify complex woodworking tasks, enabling less skilled operators to produce professional-quality results, which increases workforce flexibility and reduces training requirements.

- Advanced Features: Many CNC routers for cabinetry and furniture come with automatic tool changers, vacuum hold-downs, and software compatibility with popular design tools, enhancing workflow efficiency and ease of use.

In short, CNC wood routers combine speed, accuracy, versatility, and material efficiency to revolutionize furniture and cabinetry making, helping workshops and manufacturers increase quality, lower costs, and offer creative designs that meet modern market demands.